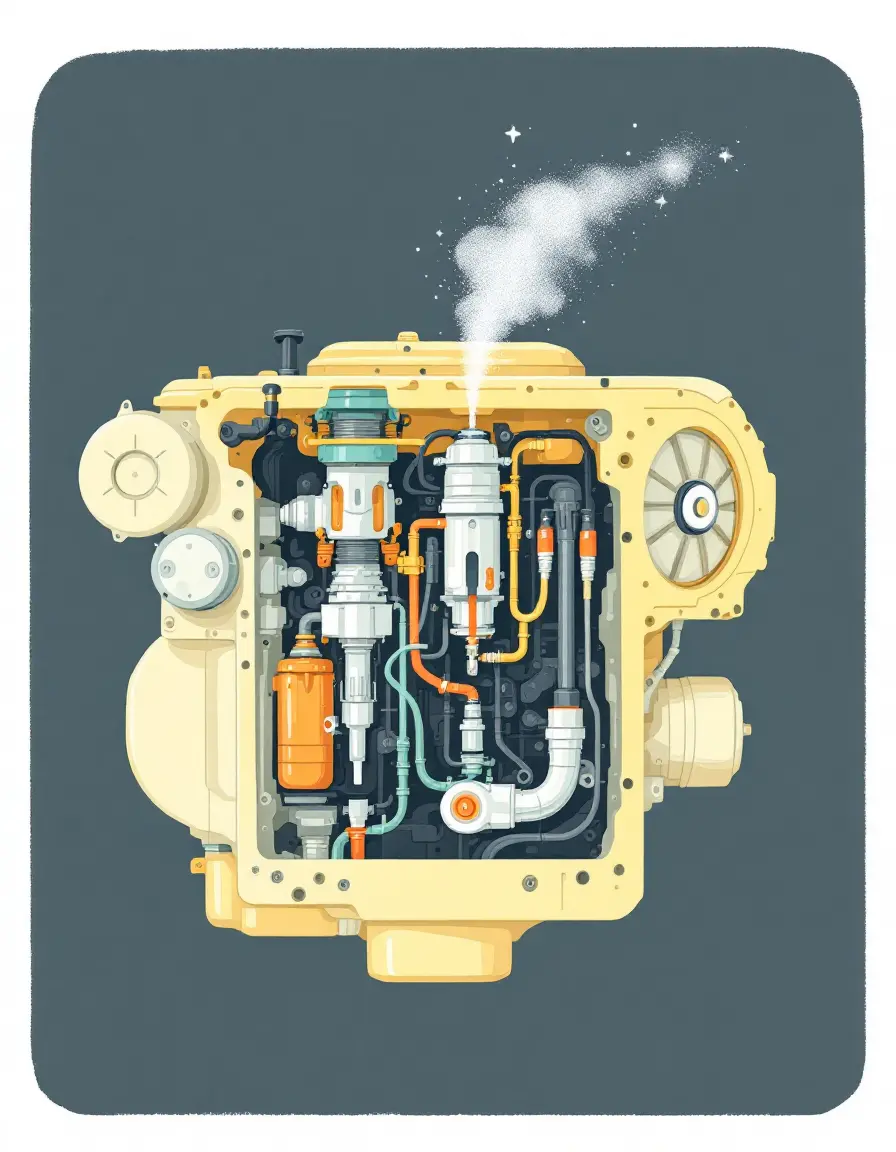

What is a diesel injection system?

Basically, the diesel fuel injection system is responsible for delivering fuel to the engine cylinders in a tightly controlled manner. Unlike gasoline engines, diesel engines use compression ignition instead of spark plugs to ignite the fuel. This means that fuel must be injected at the right time, at the right pressure, and in the right amount to ensure efficient combustion.

Fuel storage

Fuel is drawn from the tank.

Pressure increase

The injection pump increases the pressure of the fuel.

Injection

The injector sprays fuel into a fine mist.

Combustion

Fuel burns under compression

The working process is as follows:

- Fuel is drawn from the fuel tank and pressurized by an injection pump.

- Pressurized fuel is delivered to the injector.

- The injector sprays fuel into the combustion chamber as a fine mist to ensure proper fuel mixing with air for combustion.

This precision ensures optimum engine performance, fuel efficiency and reduced emissions, which are essential in both on-road and off-road diesel engine applications.

The importance of diesel injection system

Diesel injection system plays a crucial role in the efficiency and environmental impact of diesel engines. Its main benefits include:

Save fuel

Precisely controlled fuel and air mixture maximizes power output and minimizes consumption.

Reducing emissions

Modern systems meet stringent environmental standards with cleaner combustion

Increased power

Precise fuel delivery for better efficiency, ideal for heavy-duty applications.

Evolution of diesel injection technology

Diesel fuel injection systems have come a long way since their introduction. Early systems used relatively simple but inaccurate mechanical injectors. Over time, technology has advanced to meet increasing demands for better performance and stricter emissions standards.

Mechanical injection system

Early systems used mechanical pumps and injectors, which were efficient but had reduced efficiency and high emissions.

Electronic diesel control system

Advanced computers manage injection, monitor conditions and make real-time adjustments.

Common rail system (1990s)

Revolutionary diesel engine with constant fuel pressure and electronically controlled injection.

High pressure system

Modern systems operate at pressures up to 2,500 bar, improving fuel rupture and ignition.

Common maintenance problems

Despite its many advantages, diesel injection systems can be difficult to maintain. Here are some common problems encountered by diesel injection system specialists and machine operators:

Contaminated fuel

Water, dirt and debris can clog nozzles and cause wear on critical parts.

Injector wear

Precision injectors wear out over time, causing inconsistent fuel delivery and reduced efficiency.

Fuel quality sensitivity

Advanced systems are highly sensitive to low quality or low grade fuels.

High repair costs

Complex systems require specialized diagnostic tools and calibration equipment.

Tips for maintaining diesel injection systems

Regular maintenance and proper care are essential to ensure that your diesel injection system operates without problems. Here are some helpful tips to help you get the most out of your equipment:

1. Use high quality fuel.

Always use a reputable fuel supplier to ensure your diesel meets quality standards. High-quality fuel reduces the risk of contamination and prolongs the life of components.

2. Change the fuel filter regularly.

The fuel filter is your first line of defense against contaminants. It should be changed according to your engine maintenance schedule to prevent clogged injectors.

3. Invest in appropriate diagnostic tools.

Use high quality fuel

Always use a reputable fuel supplier to ensure your diesel meets quality standards. High-quality fuel reduces the risk of contamination and prolongs the life of components.

Change the fuel filter regularly.

The fuel filter is your first line of defense against contaminants. It should be changed according to your engine maintenance schedule to prevent clogged injectors.

Invest in the right diagnostic tools

Advanced diagnostic tools help you detect problems at an early stage, saving you time and money. Tools such as fuel pressure testers or electronic diagnostic systems provide accurate information about the performance of your diesel injection system.

Clean the injector periodically.

Over time, carbon deposits can build up in the injectors, reducing their efficiency. Periodic cleaning of the injectors with a kit or professional service can prevent serious problems.

Be the initiator in maintenance

Follow the manufacturer's recommended maintenance schedule for your engine and injection system. Regular inspections, oil changes, and system checks will help prevent malfunctions.

Get support from experts

If you have a complex problem, turn to an experienced diesel injection system specialist. A professional with access to advanced calibration equipment and test benches can restore your system’s performance to peak performance.

The future of diesel injection

The diesel engine industry is undergoing rapid change, with fuel injection playing a key role in the push to make engines cleaner and more efficient. Innovations such as ultra-high pressure systems, advanced air-fuel mixing technologies and intelligent fuel delivery mechanisms are shaping the future of diesel injection.

At the same time, the rise of hybrid engines and alternative fuels is impacting the diesel injection technology landscape as manufacturers look to integrate electrification and other clean energy solutions into their designs.

Intelligent system

Optimizing Fuel Distribution with AI Power

Hybrid integration

Integration with electricity use

Extra high pressure

Advanced atomization technology

Final Thoughts

Diesel fuel injection systems are engineering marvels that provide efficiency, performance and sustainability to industries. However, keeping these systems in tip-top shape requires high-quality tools, proper maintenance practices and knowledgeable professionals.

If you are a diesel fuel injection system specialist or equipment operator, never underestimate the importance of reliable tools and solutions. At InjectionPower, we are committed to supporting professionals with state-of-the-art tools, diagnostic equipment and expert advice to overcome any challenges.

Next steps

- Need tools for your diesel injection system? Discover our high-quality products designed for precision and efficiency. Register now at injectionpower.com To access world-class tools and testing equipment for diesel injection systems, get expert support, special offers, and the precision solutions you need to keep your engine running at peak performance. Don’t wait, start improving performance and efficiency today!

- If you have any questions, please contact our team of experts for advice and support tailored to your needs. Fill out the form below.

Arm yourself with the knowledge and tools to keep your diesel engine running at peak efficiency. Accuracy and efficiency start here.

Understanding Diesel Injection Systems: What You Need to Know