How to fix leaking on high-pressure diesel pipes?

The owner of a diesel engine, who is experiencing a leak from the connections of a high-pressure pipe due to worn-out cones, faces a number of challenges. The most common solution is to replace the entire pipe, but often it is not available as a standalone item and the full set of pipes comes with a high cost. Additionally, the lead time for acquiring a full set of pipes can take up to a few days, leaving the diesel engine owner without the use of their equipment.

This delay can cause significant frustration, lost productivity, and financial losses. In fact, diesel engine owners are reliant on their machinery to keep their business running smoothly so prolonged equipment downtime is unacceptable: they need to find a better solution to shorten the lost time and contain costs.

Any other options?

The only viable alternative to replacing the entire pipe is investing in a machine that allows for on-site pipe repair. This excellent solution involves cutting the leaking end and forming a perfectly shaped new cone to warrant complete sealing.

By offering on-site pipe repairs, diesel workshops can provide a level of service that exceeds customer expectations and sets them apart from the competition. A nipple-forming tool allows technicians to quickly and efficiently form new cones, reducing downtime and increasing their Customer productivity.

Overall, the unpleasant situation experienced by diesel engine owners facing high-pressure pipe leaks highlights the importance of having access to efficient and cost-effective repair solutions.

Why invest in a nipple-forming tool?

For the repair workshops that prioritize prompt customer service, investing in a nipple-forming tool is a strategic unique commercial opportunity, a money-making machine. This tool is a must-have piece of equipment that can ultimately lead to increased customer retention and business development.

In fact, by offering an efficient and cost-effective on-site pipe repair solution, workshops seeking to grow their business can build trust and loyalty with their customers. This can lead to repeat business and positive word-of-mouth recommendations, which are essential for yielding long-term benefits.

While the investment in such a machine may be challenging, the actual cost of re-manufacturing the nipple is practically zero. This means that

by leveraging on providing a time-saving and efficient level of service to the diesel engine owner,

the workshop can quickly and easily recover its investment.

Product Description

The press for forming cones on diesel injection pipes with part number 9376-D is an effective hand-operated solution for creating new cones quickly and efficiently.

In addition to the press alone, three sets of dies for different diameters are available:

- 6 mm diameter (9376-DP6),

- 6 mm diameter for common rail applications (9376-DP6CR),

- 8 mm diameter (9376-DP8).

Customers who require all three sets find it easier to order the bundle code 9376-DK1, while an electric version is available on request.

The press is very user-friendly and safe to operate. By simply setting it up with the die set corresponding to the diesel injection pipe, operators can create new cones in just a matter of minutes.

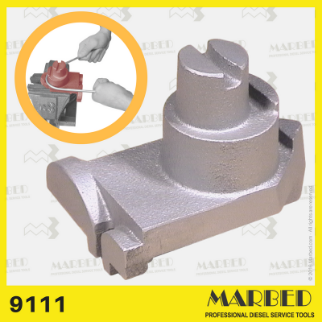

9111 is the universal jig to shape diam 6 mm high-pressure pipes

Contact InjectionPower today for more information on purchasing 9376-DK1 press and discover how to increase service workshop's profits and productivity.

Send your inquiry

Press for forming cones on high pressure diesel injection pipes